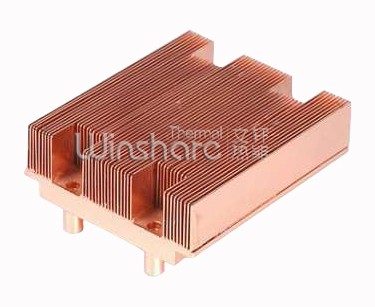

After three years of independent research and development on high-power skived fin technique, Winshare Thermal successfully applied it to Sungrow Power Supply’s 500kW central inverters. After continuous large-scale applications for years, the cumulative installed capacity in the PV industry exceeds 25GW.

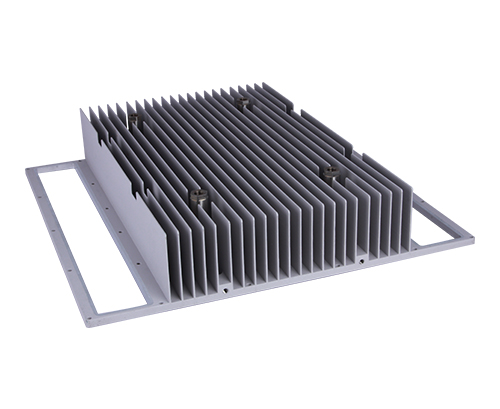

With the large-scale applications, Winshare Thermal’s skived fin technique becomes more mature and the coverage of this technique has been increased. With the gradual enhancement of the degree of automation, we demonstrate the apparent advantage from the aspects of cost and reliability. We have received the endorsement from various domestic and overseas customers in the fields of telecommunication, UPS, inverters, controllers, wind power converters, and SVG.

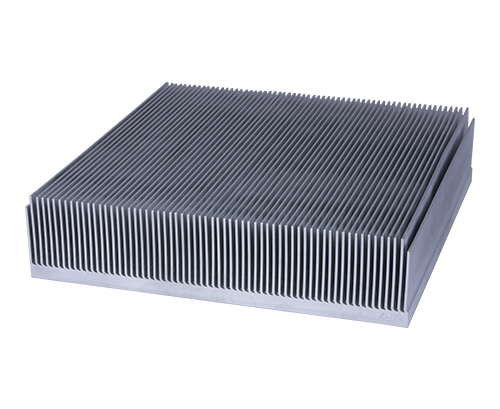

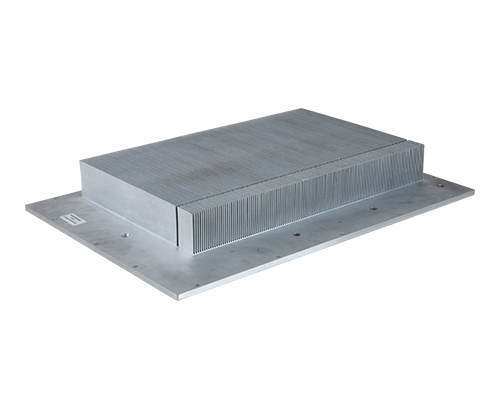

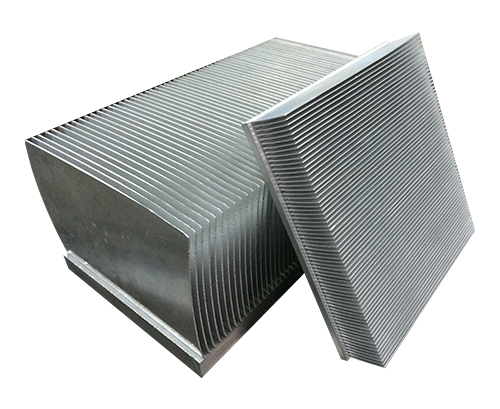

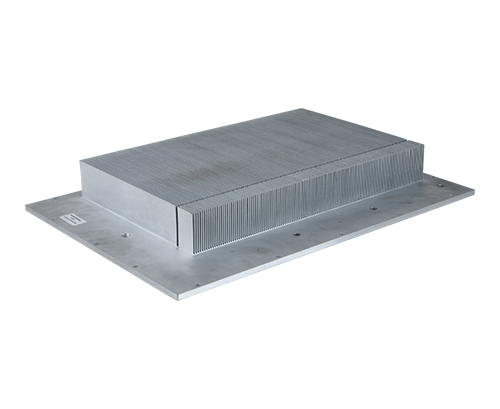

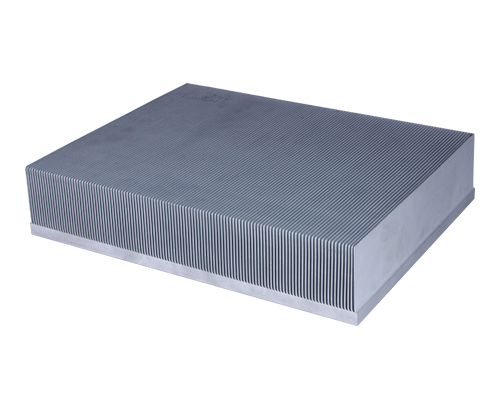

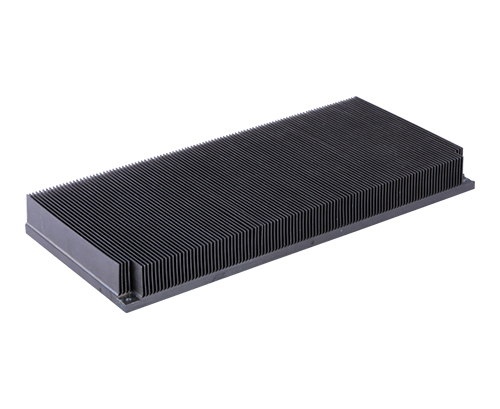

Skived fin heat sinks: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process.